This simple method reduces wastage as you are able to use your offcuts rather than having to throw them away!.These are made from the strips of shingles, by cutting the strips into the individual tile shaped "tabs" and then overlaying them over each other along the ridges or hips.Fix the felt to the board using 3mm to 3.5mm diameter barbed hot dipped galvanized roofing nails with a minimum 10mm head or glue the felt down using bitumen adhesive.In order to qualify for the Atlas Lifetime Algae Resistance Limited Warranty against black streaks caused by blue-green algae, installation must include.

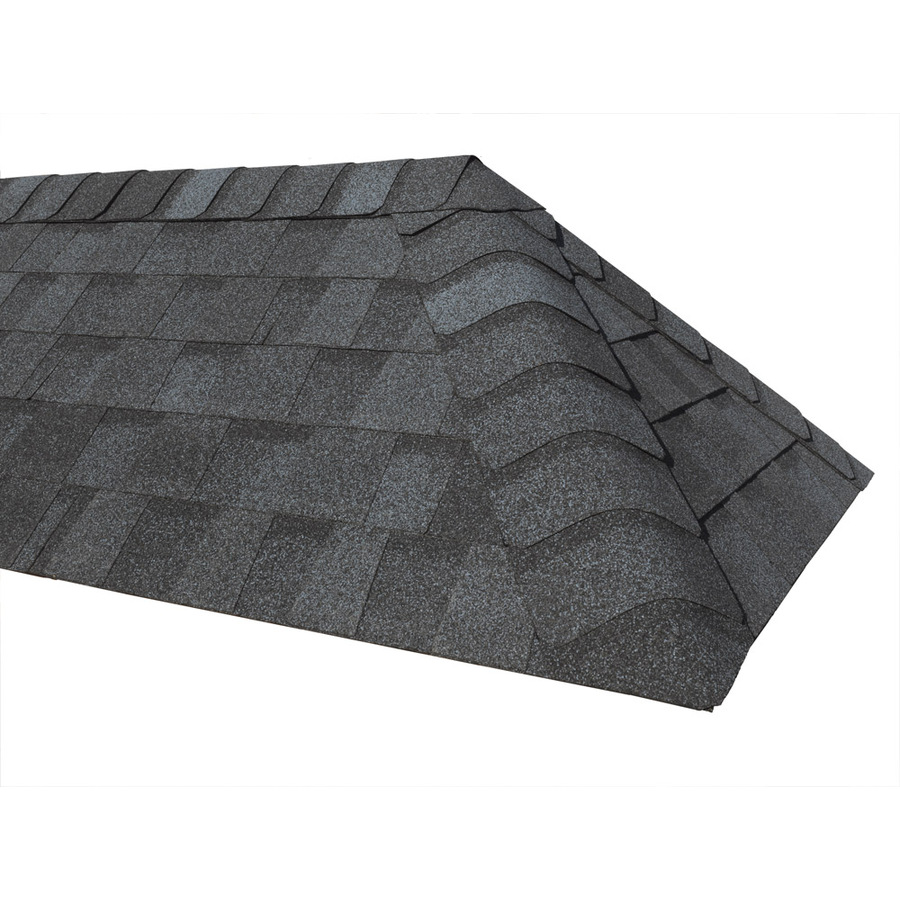

Nails must be long enough to penetrate a minimum of 20mm into the solid wood deck or just through the plywood deck.Fix the felt to the board using 3mm to 3.5mm diameter barbed hot dipped galvanized roofing nails with a minimum 10mm head.The minimum recommended weight for ridge and hip flashing is 16 oz. Most hip installations involve the weaving of copper flashing sheets between roofing shingles. The ridge flashings form a cover over the roofing material. Lay the felt with at least a 75mm lap on the joints. Atlas Hip and Ridge Shingle features Scotchgard Protector, and provides superb hip and ridge protection by capping the external angles of your roof. Seal-A-Ridge Protective Ridge Cap Shingles offer protection at high stress areas of your roof (the hips and ridges). Description: There are many ways to construct copper ridge and hip flashings.To lay these shingles at pitches greater than 15 degrees:

0 kommentar(er)

0 kommentar(er)